- Overview

- Kaugnay na Mga Produkto

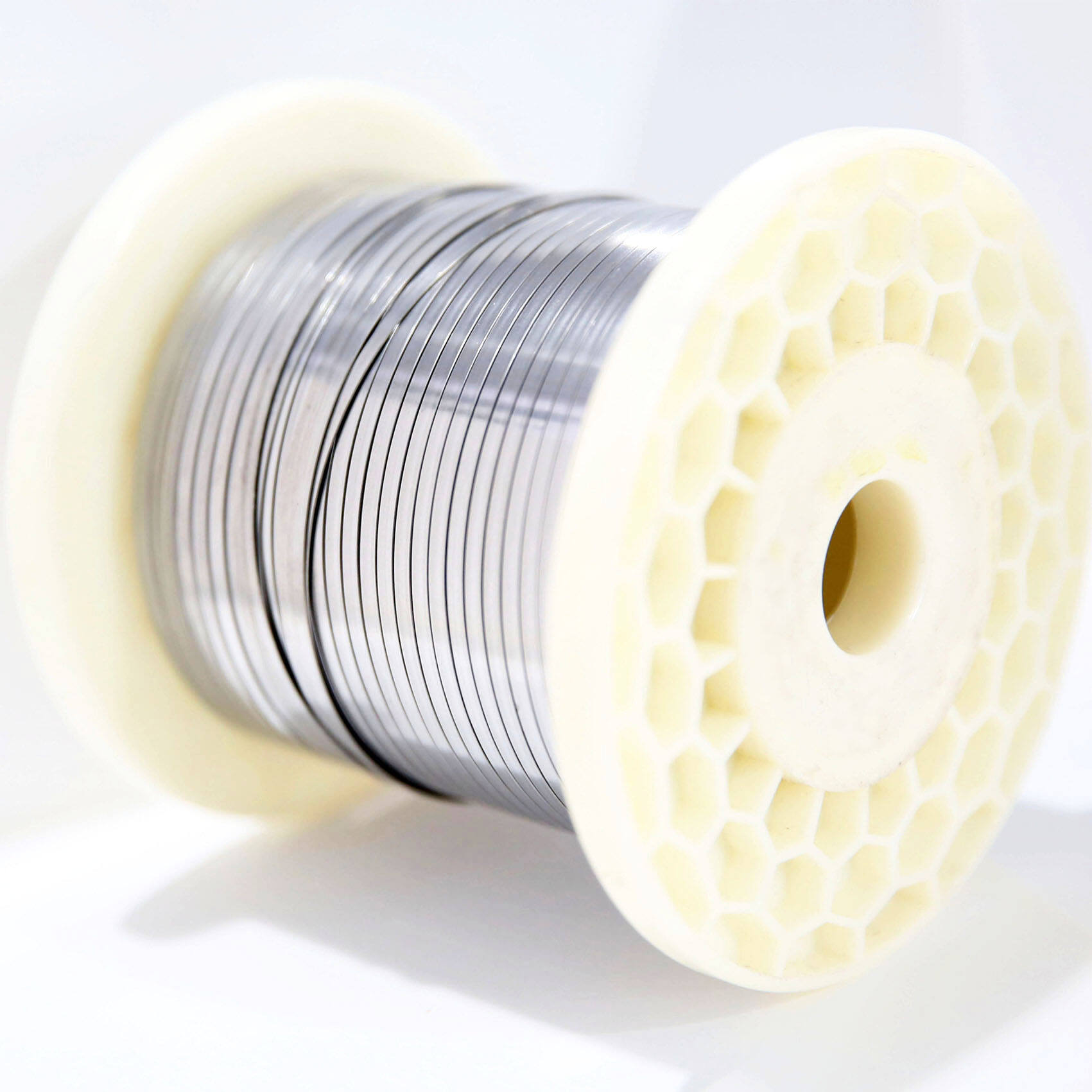

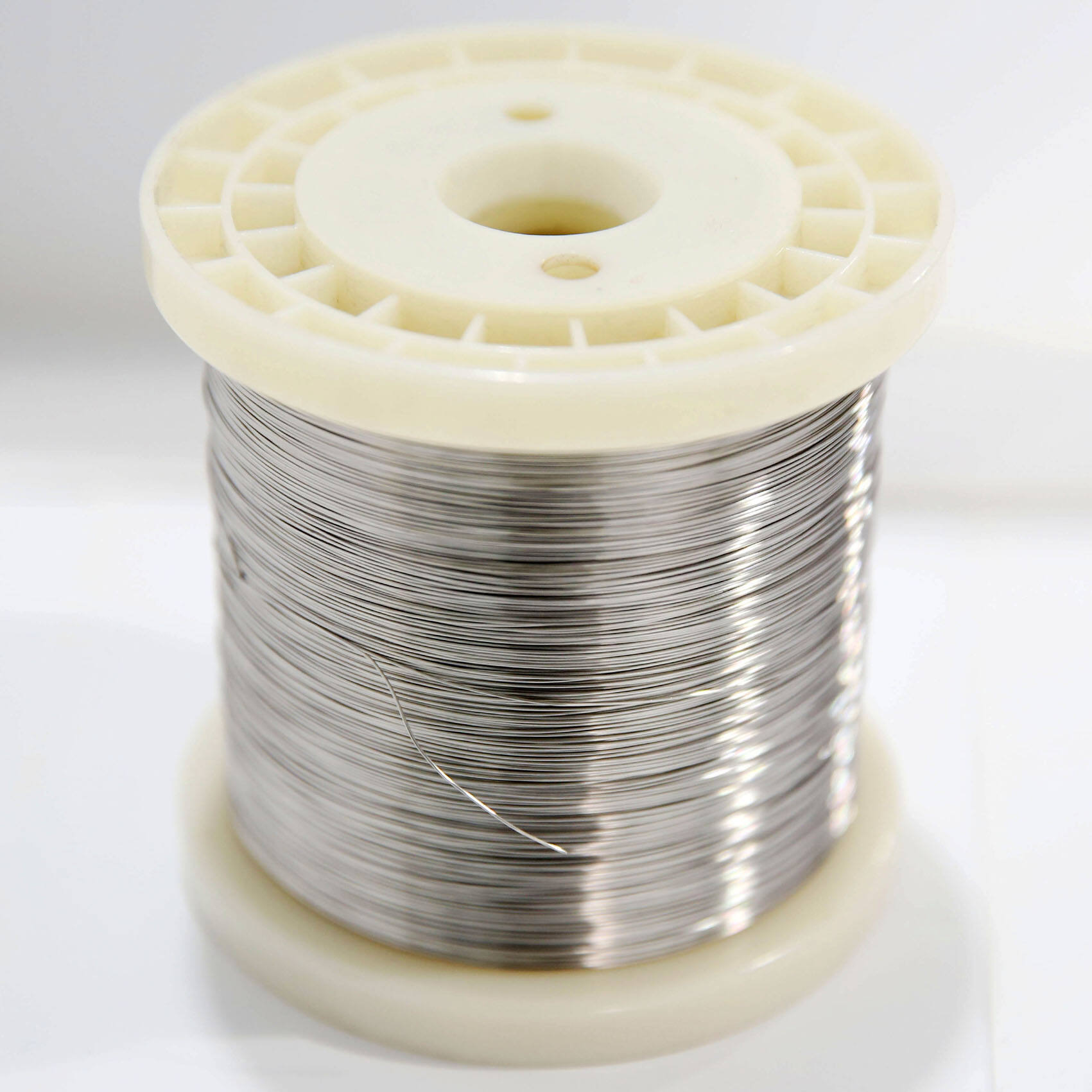

Ang Nickel-chromium wiryus, tirahan, bar at wiryus ay kaya ng paggawa ng mga elemento ng elektrikong pagsisigarilyo at pangkalahatang mga elemento ng resistensya, madalas na ginagamit sa industriyal na elektrikong hurno at iba't ibang aparato ng heat treatment, at maaaring gamitin din bilang materyales ng resistensya para sa elektронiko, elektrikal, elektrikal at iba pang industriya.

Pangunahing teknikal na mga parameter ng pagganap ng Nickel-chromium wiryus:

| Tatak | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

| Mga ari-arian | ||||||

| Pangunahing kimikal na komposisyon% | Ni | margin | margin | 55-61 | 32-36 | |

| CR | 20.0~23.0 | 28-31 | 15-18 | 18-21 | 18-21 | |

| ang | ≤1.0 | |||||

| Pinakamataas na temperatura ng paggana ng komponente℃ | 1200 | 1250 | 1150 | 1050 | 1050 | |

| Punto ng pagsasaayos℃ | 1400 | 1400 | 1400 | 1400 | 1400 | |

| densidadg⁄cm3 | 8.40 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Elektrikal na resistivityμΩ·m, 20℃ | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.04±0.05 | 1.04±0.05 | |

| Rate of pagpapahaba% | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Specific heatJ/g.℃ | 0.440 | 0.44 | 0.44 | 0.44 | 0.44 | |

| Thermal conductivityKJ/m.h℃ | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| mikroestrakturaa×10-6/℃(20~1000℃) | 18.0 | 17.0 | 17.0 | 19.0 | 19.0 | |

| mikroestraktura | austenite | |||||

| magnetismo | hindi magnetiko | |||||

Resistivity ng malambot na kawad:

| Klase ng Alloy | diameter, mm | Resistibilyad ng Elektrisidad μΩ·m(20℃) |

| Cr20Ni80 | <0.500.50~3.00>3.00 | 1.09±0.051.13±0.051.14±0.05 |

| Cr30Ni70 | <0.50≥0.50 | 1.18±0.051.20±0.05 |

| Cr15Ni60 | <0.50≥0.50 | 1.12±0.051.15±0.05 |

| Cr20Ni35 | Cr20Ni30 <0.50≥0.50 | 1.04±0.051.06±0.05 |

Strip resistivity:

| Klase ng Alloy | diameter, mm | Resistibilyad ng Elektrisidad μΩ·m(20℃) |

| Cr20Ni80 | ≤0.80>0.80~3.00>3.00 | 1.09±0.051.13±0.051.14±0.05 |

| Cr30Ni70 | ≤0.80>0.80~3.00>3.00 | 1.18±0.051.19±0.051.20±0.05 |

| Cr15Ni60 | ≤0.80>0.80~3.00>3.00 | 1.11±0.051.14±0.051.15±0.05 |

| Cr20Ni35Cr20Ni30 | <0.80≥0.80 | 1.04±0.051.06±0.05 |

EN

EN

AR

AR DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID SR

SR SL

SL UK

UK VI

VI HU

HU MT

MT TH

TH TR

TR AF

AF MS

MS GA

GA AZ

AZ MN

MN MY

MY KK

KK UZ

UZ KY

KY BN

BN