- Overview

- Related Products

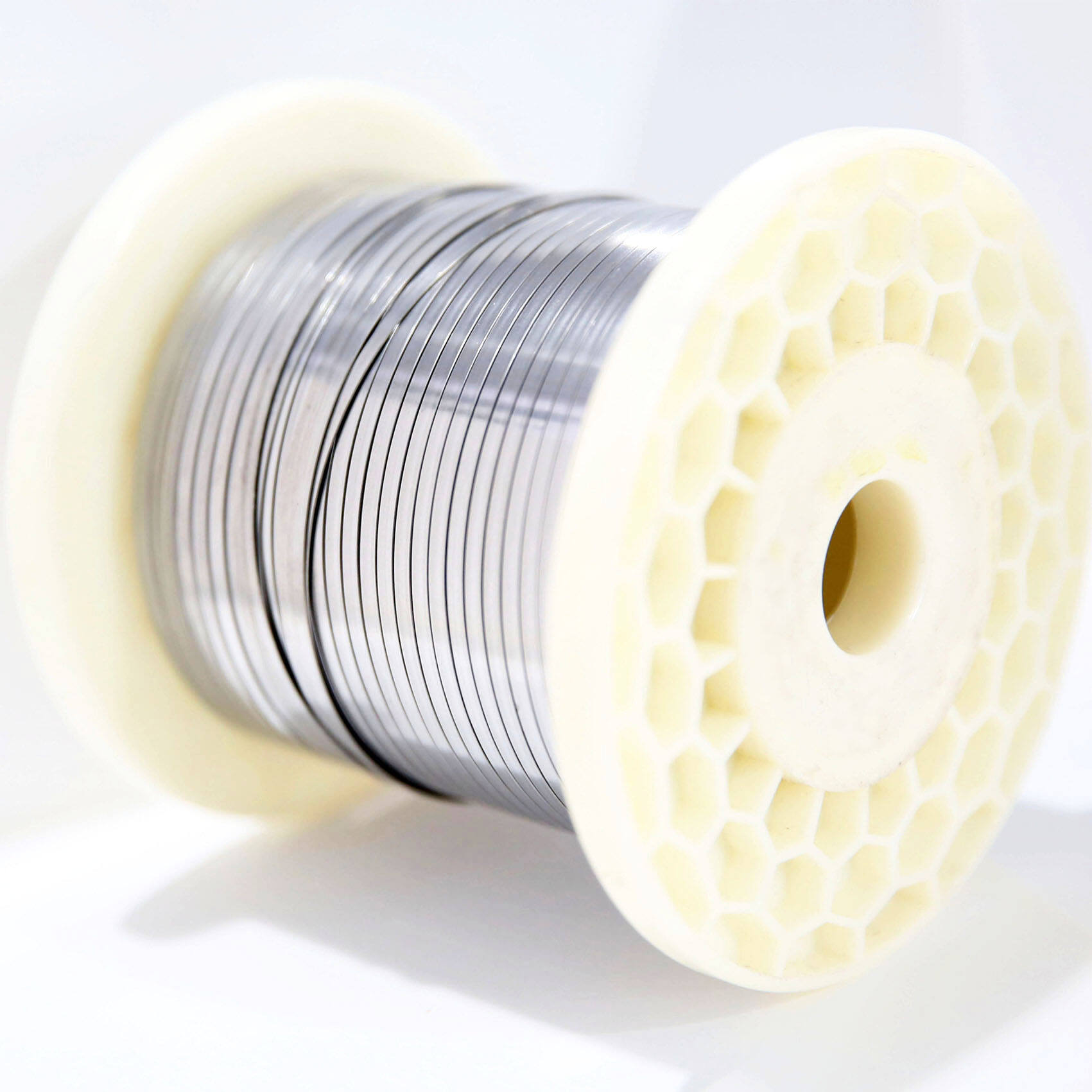

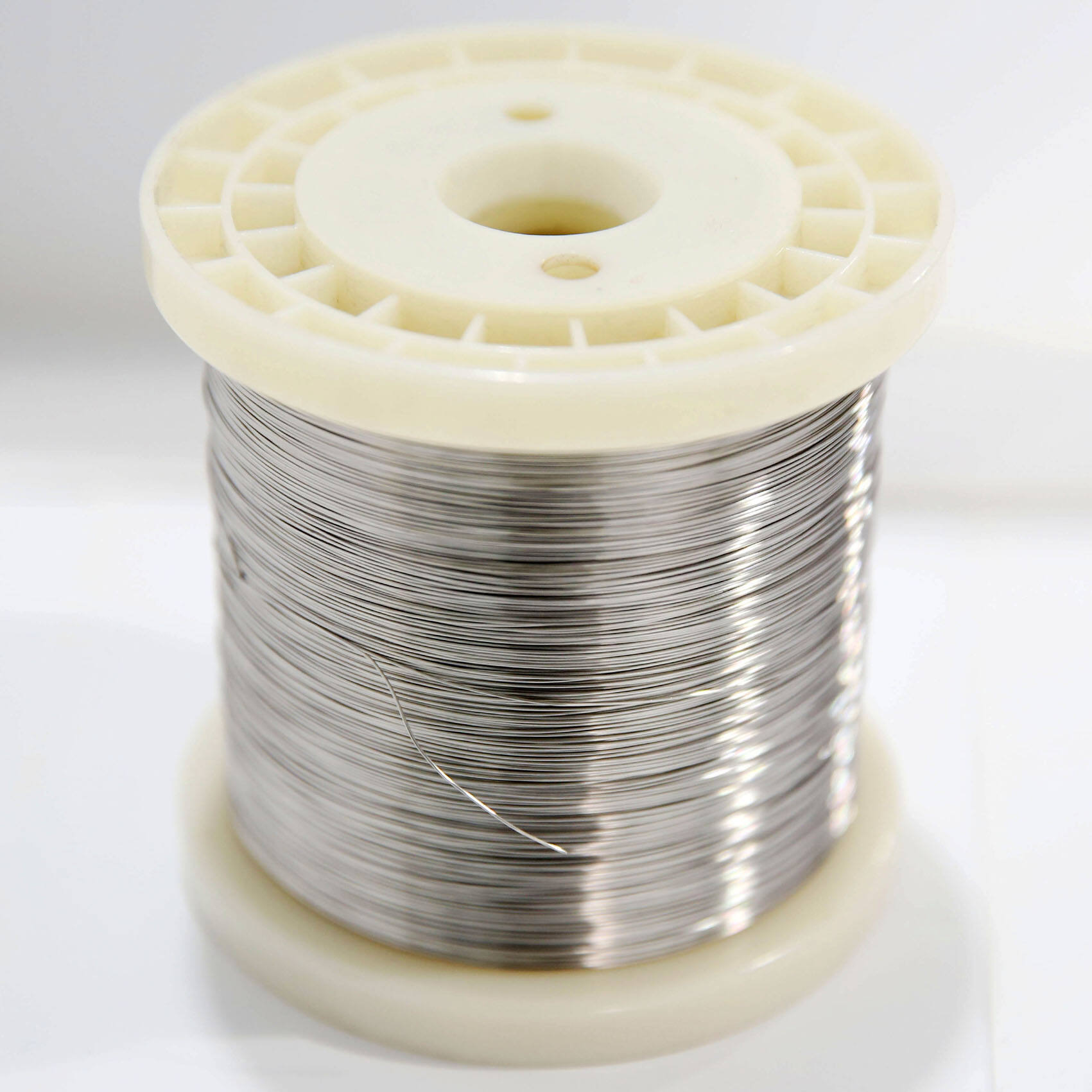

Nickel-chromium wire, strip, bar and wire are suitable for the production of electric heating elements and general resistance elements, often used in industrial electric furnaces and various heat treatment equipment, and can also be used as resistance materials for electronic, electrical, electrical and other industries.

Nickel-chromium wire main technical performance parameters:

| brand | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

| property | ||||||

| Main chemical composition% | Ni | margin | margin | 55-61 | 32-36 | |

| Cr | 20.0~23.0 | 28-31 | 15-18 | 18-21 | 18-21 | |

| Fe | ≤1.0 | |||||

| Maximum operating temperature of the component℃ | 1200 | 1250 | 1150 | 1050 | 1050 | |

| Fusing point℃ | 1400 | 1400 | 1400 | 1400 | 1400 | |

| densityg/cm3 | 8.40 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Electrical resistivityμΩ·m,20℃ | 1.09±0.05 | 1.18±0.05 | 1.12±0.05 | 1.04±0.05 | 1.04±0.05 | |

| Rate of elongation% | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | |

| Specific heatJ/g.℃ | 0.440 | 0.44 | 0.44 | 0.44 | 0.44 | |

| Thermal conductivityKJ/m.h℃ | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| microstructurea×10-6/℃(20~1000℃) | 18.0 | 17.0 | 17.0 | 19.0 | 19.0 | |

| microstructure | austenite | |||||

| magnetism | nonmagnetic | |||||

Soft wire resistivity:

| Alloy grade | diameter,mm | Electrical resistivityμΩ·m(20℃) |

| Cr20Ni80 | <0.500.50~3.00>3.00 | 1.09±0.051.13±0.051.14±0.05 |

| Cr30Ni70 | <0.50≥0.50 | 1.18±0.051.20±0.05 |

| Cr15Ni60 | <0.50≥0.50 | 1.12±0.051.15±0.05 |

| Cr20Ni35 | Cr20Ni30 <0.50≥0.50 | 1.04±0.051.06±0.05 |

Strip resistivity:

| Alloy grade | diameter,mm | Electrical resistivityμΩ·m(20℃) |

| Cr20Ni80 | ≤0.80>0.80~3.00>3.00 | 1.09±0.051.13±0.051.14±0.05 |

| Cr30Ni70 | ≤0.80>0.80~3.00>3.00 | 1.18±0.051.19±0.051.20±0.05 |

| Cr15Ni60 | ≤0.80>0.80~3.00>3.00 | 1.11±0.051.14±0.051.15±0.05 |

| Cr20Ni35Cr20Ni30 | <0.80≥0.80 | 1.04±0.051.06±0.05 |

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

AZ

AZ

MN

MN

MY

MY

KK

KK

UZ

UZ

KY

KY

BN

BN