- Overview

- Related Products

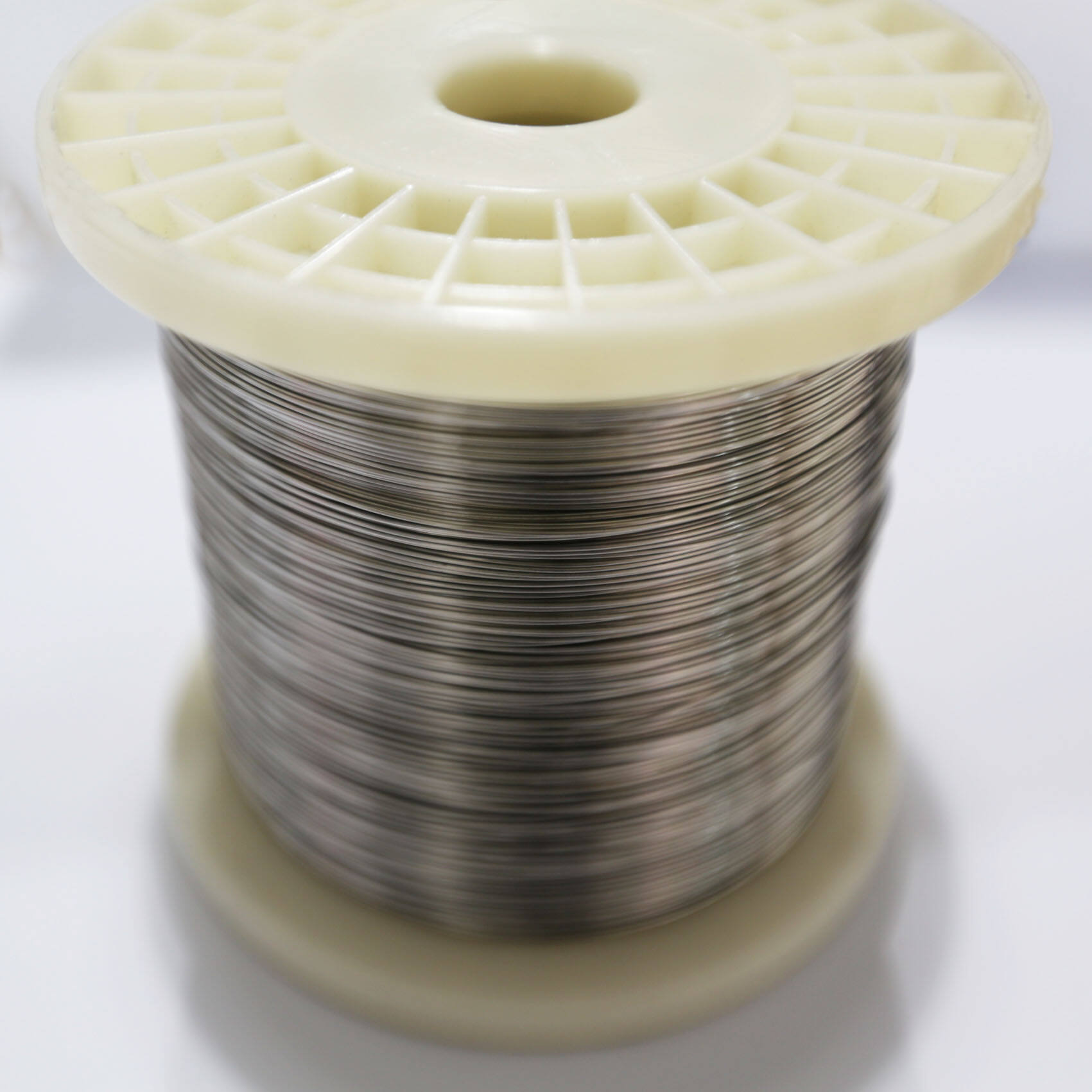

Kamal alloy nickel, chromium, aluminum, iron as the main components, the resistivity is about three times higher than manganese copper, and has a low resistance temperature coefficient and low thermoelectric potential against copper, good long-term resistance stability and oxidation resistance, suitable for the production of micro resistance components.

Technical parameter table:

| Alloy grade | Electrical resistivity (20 ℃Ω m㎡/m) | rank | Average resistance temperature coefficient | Average heat to copper Electromotive force rate | |||

| Applicable temperature (℃) | α1 10-6/℃ | Applicable temperature (℃) | α2 10-6/℃ | 0~100℃ μ V/ ℃ | |||

| 6J22 | 1.33±0.07 | 1 2 3 | -55~20 | -5~+5 -10~+10 -20~+20 | 20~125 | -5~+5 -10~+10 -20~+20 | ≤2.0 |

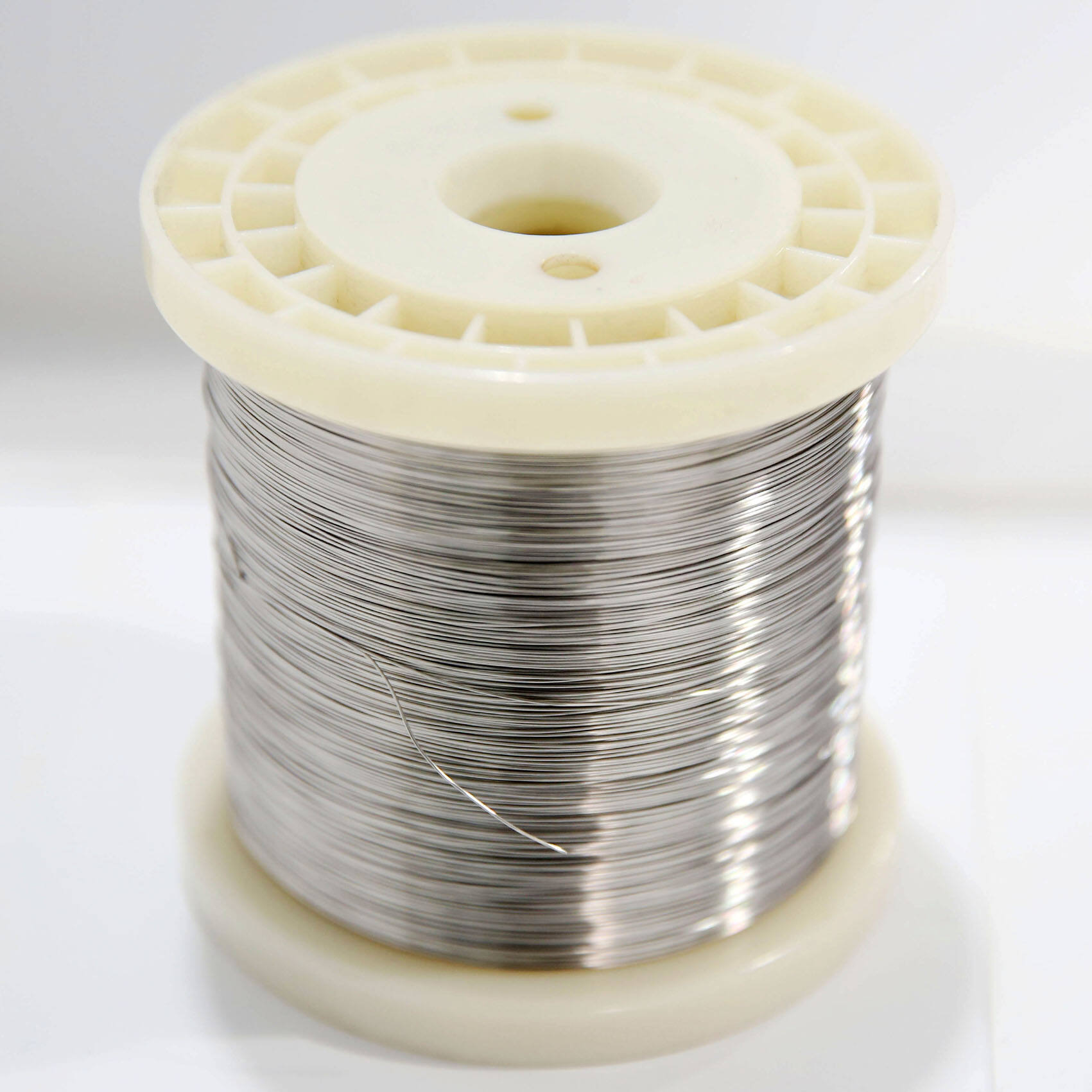

The chemical composition of Monel400 alloy is composed of 30%Cu and 65%Ni plus trace Fe(1%-2%). It is more resistant to the corrosion of reducing media than pure nickel, more resistant to the corrosion of oxidizing media than pure copper, has good high temperature corrosion resistance and oxidation resistance, excellent hot and cold processing and welding process performance, and has satisfactory thermal strength and high plasticity below 700℃.

EN

EN

AR

AR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

AZ

AZ

MN

MN

MY

MY

KK

KK

UZ

UZ

KY

KY

BN

BN